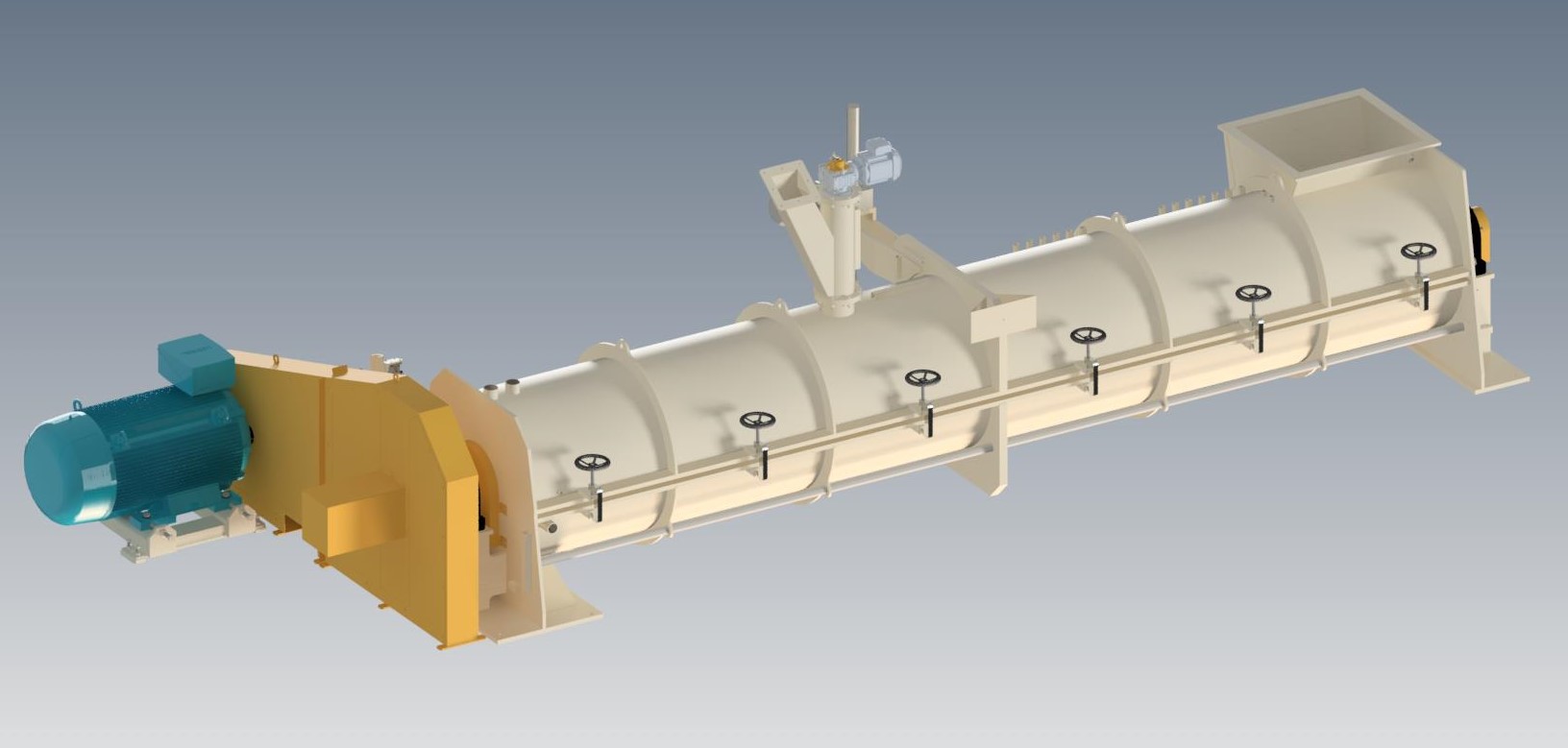

“BBL” Glue Blenders

Products

“BBL” Glue Blenders

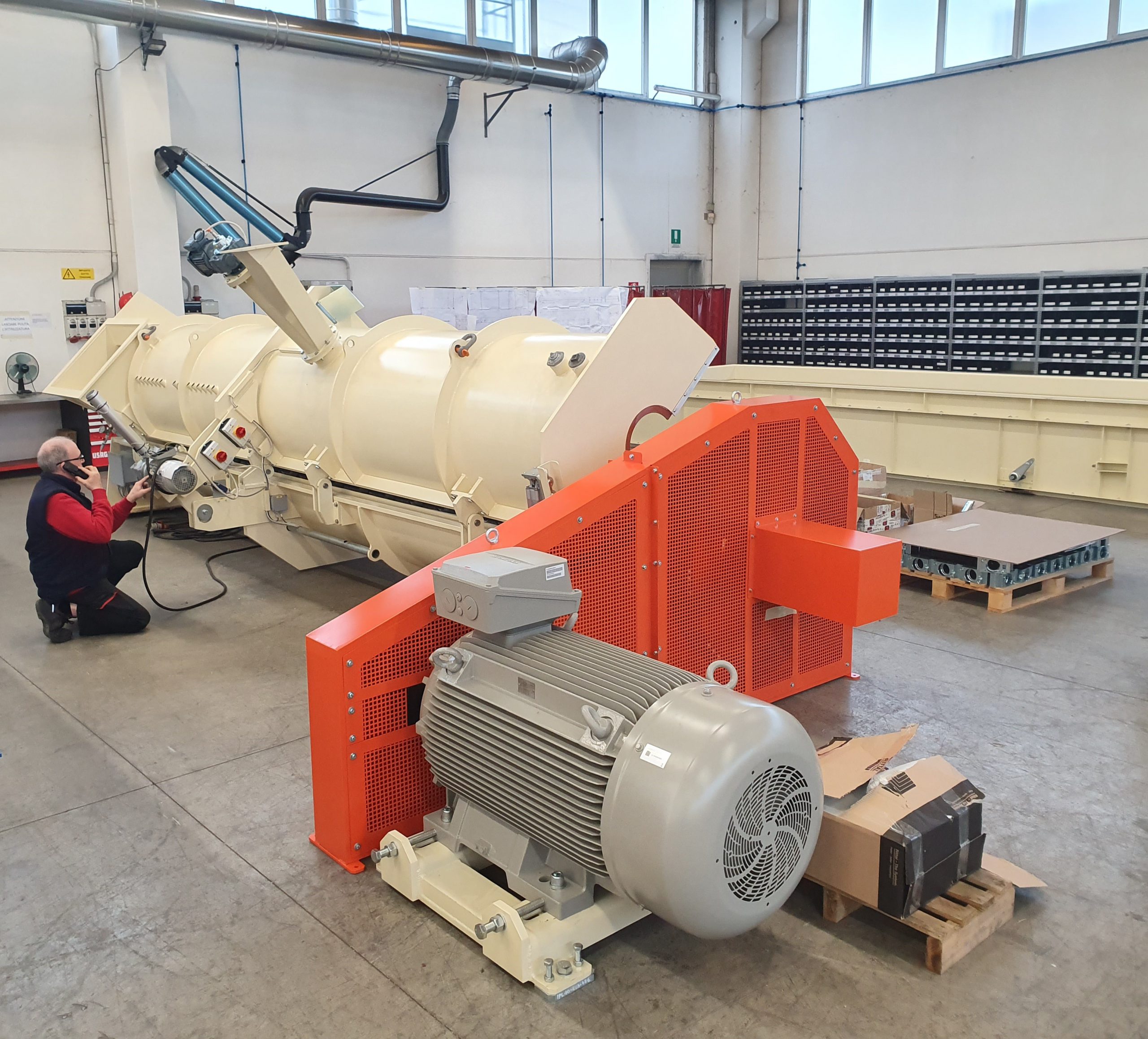

Gentle and effective mixing of wood particles and glue. Whenever the process requires the mixing of wood shavings, the question arises of how to preserve the geometric shape of the wood shavings. Preserving the shape is particularly important because an excessive reduction in particle size would generate dust that would cause stains in the finished product and an increase in glue consumption. The “BBL” BULLMECH glue blenders guarantee longer retention and mixing times; in this way the centrifugal effect is reduced with a consequent reduction of impacts and dust production. The specific construction of the machine allows separate cooling of the shell (with three independent circuits for the base, cover and feed hopper), rotor and mixing tools.

The inner shells of the glue blenders can be supplied with special wear-resistant inner coatings to meet even the most severe operating conditions. In addition, the material can be fed with two types of rotors:

- “SLF” type glue blenders are equipped with crescent-shaped tools (paddles) to provide a better introduction of the SL chip into the mixing chamber;

- “CLF” type glue blenders are equipped with a spiral drum that introduces the CL chip into the mixing chamber minimizing the impact between the particles.

The adoption of advanced design solutions makes it possible to install BULLMECH glue blenders even in dusty and potentially explosive areas as required by ATEX regulations.

Benefits

- Reduced fragmentation of wood particles

- Homogeneous distribution of the glue in the chips

- Maximum cleanliness during operation

- Reduced glue consumption

Download the technical data sheet of this product

Download

Request information

Contact our offices now to ask for more information about our services, learn about our technology and request a quote tailored to your needs. Our team is at your complete disposal.